About us

Alcon is a Greek manufacturing company with more than twenty years of experience, demonstrating all these years a high level of professionalism and excellent customer relationships. The company's products include, inter alia, aluminum and synthetic window frames, central entrances, shutters, railings, thermal insulating glazing, pergolas and railings. The company's exclusive goal remains the quality of its products and the continuous development. Alcon's products are distinguished for their perfect aesthetics and guarantee the highest quality standards of thermal and acoustic insulation, safety and perfect functionality, thanks to the excellent materials used for their manufacture. For this reason, the company works with the largest suppliers of raw materials and accessories for frames.

With state-of-the-art technology, it can easily meet the demands of its customers, who are always beside them, in order to realize their dreams, with the ultimate goal of creating a better quality of life.

The company invests in capital and manpower so that it can produce excellent products at affordable prices, always focused on the ultimate happy customer.

Her collaboration with leading foreign firms always gives her excellence, both in her products and in the development of new ones. It cooperates with names such as Schüco (Aluminum & PVC profiles, Mechanisms), Alumil (Aluminum Profiles), Elvial (Aluminum Profiles), Aluminco (Railings & Shelters), GU (Mechanisms), Winkhaus (Locks) (knobs), Dr.Hahn (hinges), Roto (mechanisms), Saint Gobain, AGC, Guardian, etc.

Company history

1992 The company alcon was founded in Xino - Nero, Florina by Mr. Stefanos Papastefanou in 1992 as an individual company with main occupation the construction of aluminum frames.

2002 The individual company was transformed into a Limited Company under the supervision of Mr. Konstantinos Papastefanou, who transferred it to new privately owned 750m2 building premises on a 15.000m2 plot. In the same space an exhibition of the company's products and offices is being created. The company's mechanical equipment is renewed and an automatic CNC production line for aluminum frames is installed. He works with the companies elvial and SCHÜCO.

2005 A production line of pvc frames is installed, where it works exclusively with SCHÜCO, manufacturing high-quality frames.

2008 Expansion of the building facilities of the company by 700m2, resulting in more than 1,500m2 covered production areas.

2009 Establishment of the company's capacity by installing a CNC double-pan heat-insulating glazing line.

2010 Installation of Factory Production Control (FPC) for continuous improvement of the products manufactured by the company. Certification of frames with the CE mark. Collaboration with ALUMINCO for the disposal of aluminum rails and shelters.

2011 Collaboration with SCHÜCO (solar) and installation of home photovoltaic systems up to 10KW. The company undertakes the installation of "turnkey" photovoltaic systems, the reason why its customers trust it.

2012 Collaboration with ALUMIL. And disposal of its systems. Working with SALAMANDER and placing StreamLine.

2013 Creation of the PREMIUM line of inputs for its distribution abroad.

2014 Establishment of a subsidiary based in Germany dealing with the wholesale trade of window frames.

2015 Expansion of the company's activity and creation of a pvc and aluminum roll forming unit.

Vision

Alcon is in constant vigilance, watching closely the latest developments in the window frames. With a vision of continuous improvement of its products and the development of new ones.

SHOWROOM

Do you have any questions about our products? Do you want to consult us and discuss your work with us?

Come to our show to see our products nearby. Here is a fully refurbished space with plenty of samples, drawings and colors to keep you up to date.

Exhibition hours:

Monday - Friday : 09:00 έως 18:00.

Saturday : 10:00 - 15:00 (by appointment!)

Please let us know about your visit so we can arrange for you to spend enough time for you ...

We welcome you!

Image Video

Quality

Alcon has strict quality criteria. From designing, controlling the production process (FPC), cutting and assembly to packaging and shipment of its products. As far as the CE marking is concerned, all the products of the company now have a unique id number, which helps in the traceability of its products.

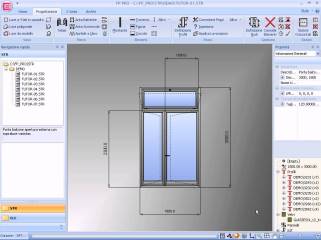

Product design is made by experienced and skilled staff with modern programs (autocad). These executives are also responsible for designing new products (R & D), which, after control, integrate them into the production process.

The FPC (Factory Production Control) applied to our company requires us to make continuous inspections throughout the production process from the receipt of the Rolling Shutters, cutting, assembly, glazing installation, packaging to the placement of frames in the building. Specially trained crews place our cases on the basis of instructions and specifications of international standards, with all the necessary small parts necessary for the proper fitting of the frame in the building.

Company facilities

[ Production ]

CNC design

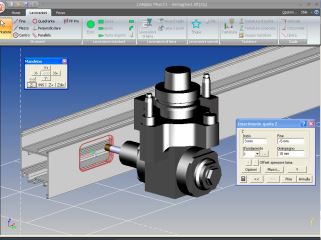

The measurement of your frames in the building, the ordering of the raw materials and their inspection upon receipt is done by experienced and skilled personnel with long experience in the industry. All the design of the constructions that the company produces is made with modern equipment and special design programs, especially for the production of frames. Profile treatments are also done with special software in state-of-the-art CNC machining centers.

Production of aluminum frames

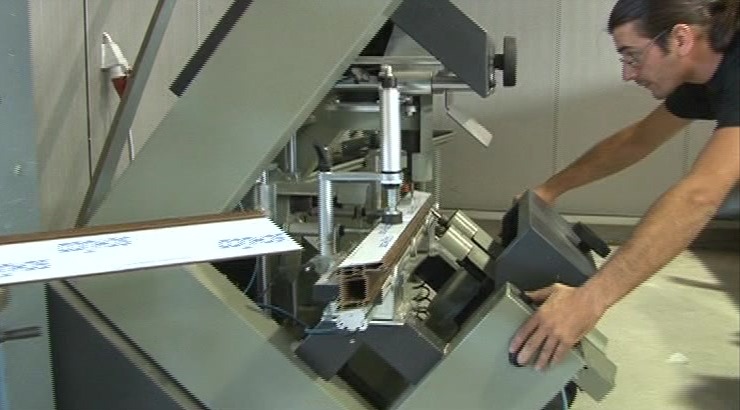

The company has a production line for aluminum frames and special constructions. In this line, it manufactures aluminum frames, aluminum-wood windows, curtain walls and atriums. Production is CNC with all machines connected online.

Production of PVC frames

The company also has a production line for synthetic frames. All stages of the production process are of high quality and with the latest technology. Experienced and skilled staff, builds a number of frames in many typologies, as well as special constructions.

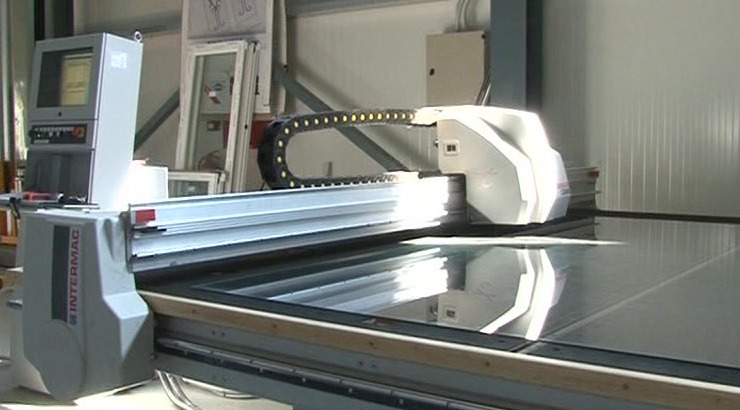

Manufacture of heat insulating glass

With regard to the glass panes manufactured by the company, and here are all CNC. Automatic low-e coating, automatic cutting of straight cuts, automatic mold cutting, glazing with noble gases (90% argon). With its machines the company has the ability to manufacture double and triple glazing with high insulation, safety and sound insulation of various kinds, depending on the customer's needs.

Packaging and Transportation

The packaging of the products of the company is also made with special packaging machines, in order to get your products intact in the space of your building. The frame is a delicate product for this and must be packed properly. The transportation of your frames takes place with the company's own fleet in every corner of Greece, but even abroad.